Washing

Machines

BENTELER offers a wide range of washing machines for flat and curved glass.

Glass Washing Machines

We can meet the various requirements of glass manufacturers. All BENTELER Washing Machines convince due to its excellent washing quality and is available for different washing speeds.

For individual customer demands, BENTELER offers a modular washing machine. Depending on requirements, the modules are assembled according to the required cleaning tasks. Consistent high cleaning results are achieved by the combination of powerful polishing, cleaning and flushing aggregates.

The tecWasher model family is a standardized, modular concept for small and medium-sized glass formats as an especially cost-effective alternative to the customized, individual washing machines. This concept stands out due to its efficiency and its space-saving concept.

Advantages

Excellent washing and drying quality:

- Spraying zones from above and below

- Two or three washing sets with cylindrical brushes

- A tank with pump and heating for each washing set

Flexibility:

- Motorized glass thickness adjustment

- Continuously variable transport speed

Small dimensions:

- Especially compact design

- Ventilator and cabinet are directly integrated in the machine

Low operating costs:

- Compressed air not necessary

- Water-conserving cascading system

Simple, comfortable operation:

- Every tank is removable

- Easy accessibility to all modules

| Technical data | Fields of application |

|---|---|

| Architectural Glass Automotive Glass Technical Glass |

The tecWasher Compact model family is a high quality washer for small and medium-sized glass formats.

Advantages

Excellent washing and drying quality:

- Spraying zones from above and below

- Two or three washing sets with cylindrical brushes

- Reliable drying by two drying knife pairs

Flexibility:

- Motorized glass thickness adjustment

- Continuously adjustable transport speed

- Especially small, minimal glass dimensions

Small dimensions:

- Especially compact design

- Blower location above the machine

Low operating costs:

- Compressed air not necessary

- Water-conserving cascading system

- Maintenance-free machine components

Simple, comfortable operation:

- Tank is removable in one piece

- All tank connections with quick release connector

| Technical data | Fields of application |

|---|---|

| Architectural Glass Automotive Glass Technical Glass |

Advantages

Excellent washing and drying quality:

- Spraying zones with up to 10 bar

- Water filter with soiling indicator

- Automatic measurement and correction of the water conveyance

- Oscillating disc-type brushes reliably detach soiling and oxide coatings from the glass surface

- Permanent monitoring of the rinsing water quality

- Cylindrical brushes with various bristles types

- Individual configuration of the drying zones

Flexibility:

- Customized configuration through modular design

- Motorized glass thickness adjustment

- Continuously adjustable transport speed

- Integration into the complete production line

Low operating costs:

- Water-conserving cascading system

- Maintenance-free machines components

- Consumption and cleaning effort in the washing zones

| Technical data | Fields of application |

|---|---|

| Architectural Glass Automotive Glass Technical Glass |

The BENTELER Coating Washer prepares optimally the glass for the following coating process. Constant high cleaning results through a combination of high-performance polishing, cleaning, and rinsing zones are achieved.

Advantages

Washing and drying quality:

- Air filtering up to EU 13 with soiling indicator depending on customer requirements

- Spraying zones with up to 10 bar

- Automatic measurement and correction of the water conveyance

- Oscillating disc-type brushes reliably detach soiling and oxide coatings from the glass surface

- Permanent monitoring of the rinsing water quality

- Cylindrical brushes with various bristles types

- Individual configuration of the drying zones

Flexibility:

- Customized configuration through modular design

- Motorized glass thickness adjustment

- Special solutions

- Integration into complete production line

Low operating costs:

- Maintenance-free machine components

- Effective separation of polishing and cleaning zones; prevents the drag-over of polishing agents into the washing zones, thereby lower polishing agent consumption and cleaning effort in the washing zones

| Technical data | Fields of application |

|---|---|

| Architectural Glass Automotive Glass Technical Glass |

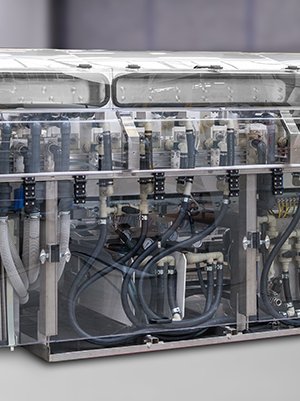

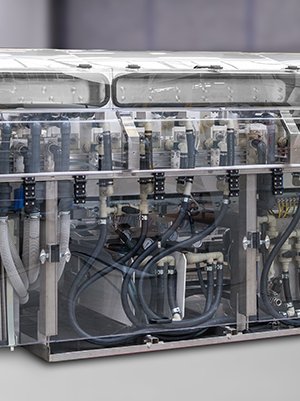

The BENTELER LAB-Washer is marked by enormous diversity. Its areas of application are found in cleanrooms or any place demanding complex washing tasks. The BENTELER LAB-Washer is made completely of synthetics in the washing zone. Its modular design allows flexibility for various application cases. The washing machine can therefore be configured according to your wishes.

Advantages

Excellent washing and drying quality:

- Assembly in company cleanrooms

- Air filtering up to EU 13 with soiling indicator depending on customer requirements

- Spraying zones with up to 140 bar

- Double housing prevents the introduction of machine-induced particles

- Ionizing device

- Ultrasonic cleaning with up to 950 kHz

- Cylindrical brushes with carbon-free bristles

Flexibility:

- Customized configuration based on modular design

- Machine upgrade possible

High process reliability:

- Integrated process monitoring at every individual station

Simple, comfortable operation:

- Easy accessibility of all construction areas from above

- Modern control with touch-screen and advanced visualization

| Technical data | Fields of application |

|---|---|

| Architectural Glass Technical Glass |

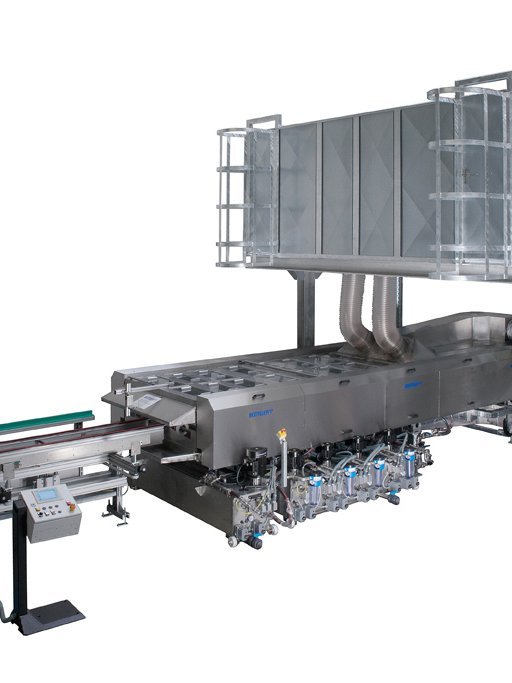

The BENTELER Washing Machine for curved windshields and car top glasses is distinguished by its excellent washing quality and is available for different washing speeds. The Washing Machine is worldwide accepted by OEM producers.

Advantages

Excellent washing and drying quality:

- Pre-spraying zones for a high quality cleaning

- Brush washing zone with cylindrical brushes for effective cleaning

- Adjustable drying nozzles for optimal drying of the curved lites

Flexibility:

- Brushes can be lifted for high pressure cleaning of thinner glasses

- Conveyors are width adjustable for different glass dimensions

Process reliability:

- Best water quality due to a high capacity water filter

- Secure hold of the glass due to down devices in the brush area

- Long lifetime due to the use of high quality machine components (stainless steel)

- Minimal maintenance costs due to easy accessibility

Simple, comfortable operation:

- Simple glass handling due to continuous operation

- Simple operation with recipe memory

| Technical data | Fields of application |

|---|---|

| Automotive Glass |

Die BENTELER Waschmaschine für gebogene Seitenscheiben und Dachgläser ist speziell auf die Anforderungen für die Bearbeitung von gebogenem Glas ausgelegt. Sie sichert eine hohe Wasch- und Trockenqualität durch speziell entwickelte Abläufe.

Advantages

Automatic brush contact adjustment:

- Excellent washing quality due to a special nozzle and brush design

- Best drying quality because of adjustable drying nozzles

Low maintenance

- made of high-quality materials

- Low noise level

- Low glass temperature after drying

| Technical data | Fields of application |

|---|---|

| Automotive Glas |

The BENTELER Thin Glass Washingmachine is marked by enormous diversity. Its areas of application are found in cleanrooms or any place demanding complex washing tasks. The BENTELER thin-glass washing machine is made completely of synthetics in the washing zone. Its modular design allows flexibility for various application cases. The washing machine can therefore be configured according to your wishes

Advantages

- Highest washing and drying quality

- Installation in the in-house clean-room

- Spray zones with up to 140 bar

- Double housing prevents the introduction of machine-induced particles

- Ultrasonic cleaning with up to 950 kHz

- Cylinder brushes with carbon-free bristles

| Technical data | Fields of application |

|---|---|

| Technical Glass |

The BENTELER vertical washing machine can be used as a single machine or in combination with a vertical drilling or grinding machine. The machine structure has been made up of steel elements which guarantee stability and long-lasting time period under heavy production conditions.

Advantages

- Excellent washing quality

- high corrosion resistance

Flexibility

- Can be used to wash rectangular or shaped glasses

High Process reliabilty:

- Integrated process monitoring at every individual station

Simple, comfortable operation:

- Easy accessibility of all construction areas from above

- Modern control with touch-screen and advanced visualization

| Technical data |

|---|

|