Glass Drilling Machines

The BENTELER Drilling Machines for flat glass are suitable for all drilling and milling operations in single and serial production even for coated glass. The BENTELER machines guarantee a high repeatability with minimal setup time for optimal cost efficiency and high flexibility.

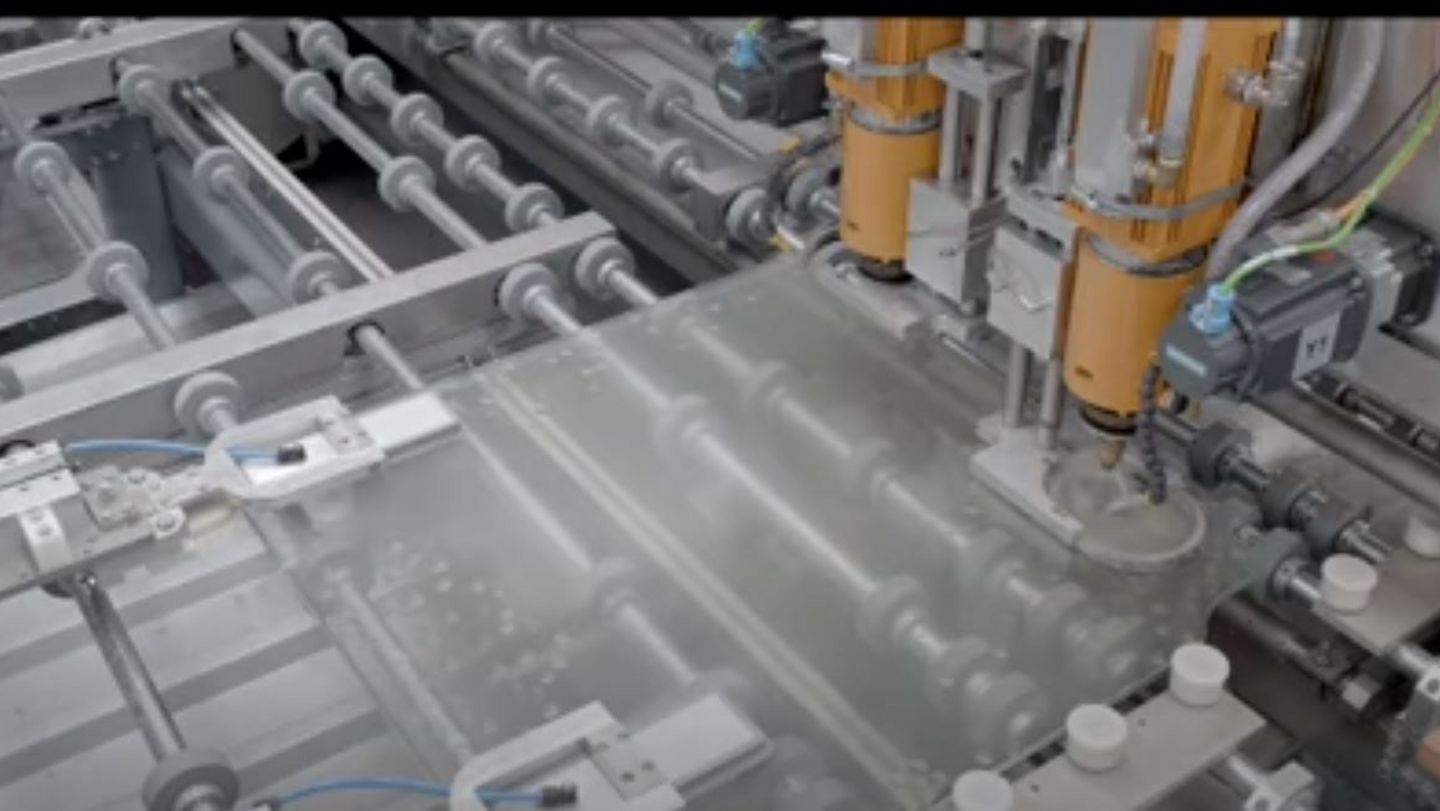

tecDriller

The BENTELER Portal Drilling Machine is a reliable process drilling machine and especially suitable for larger sizes of coated and uncoated glass. From one spindle pair up to max. two spindle pairs, the portal drilling machine covers all usual products. CNC-controlled axes and excellent repeatability guaranteed with minimal setup time for optimal cost efficiency and high flexibility.

Advantages

High precision:

- Dynamic CNC positioning of hole coordinates

- Automatic tool offset and calibration system

Flexibility:

- Two independent pairs of drilling spindles

- High performance milling spindle with speeds at 10000 min -1

- Automatic tool changer with 10 or 20 tool positions

Process reliability:

- Fully enclosed drilling spindle

- Separate milling spindle

- Modern CNC-operation

Simple operating:

- Easy user interface of hole pattern programming

- Fully automatic programs for drilling and countersinking

- Data input parallel to production

- Integration in customized software

Technical data

- Max. glass size: 3.300 x 20.000 mm

- Glass thickness: 3 – 21 mm

- Positioning speed: 64 m/min

- Milling speed: 600 mm/min

Fields of application

Architectural Glass

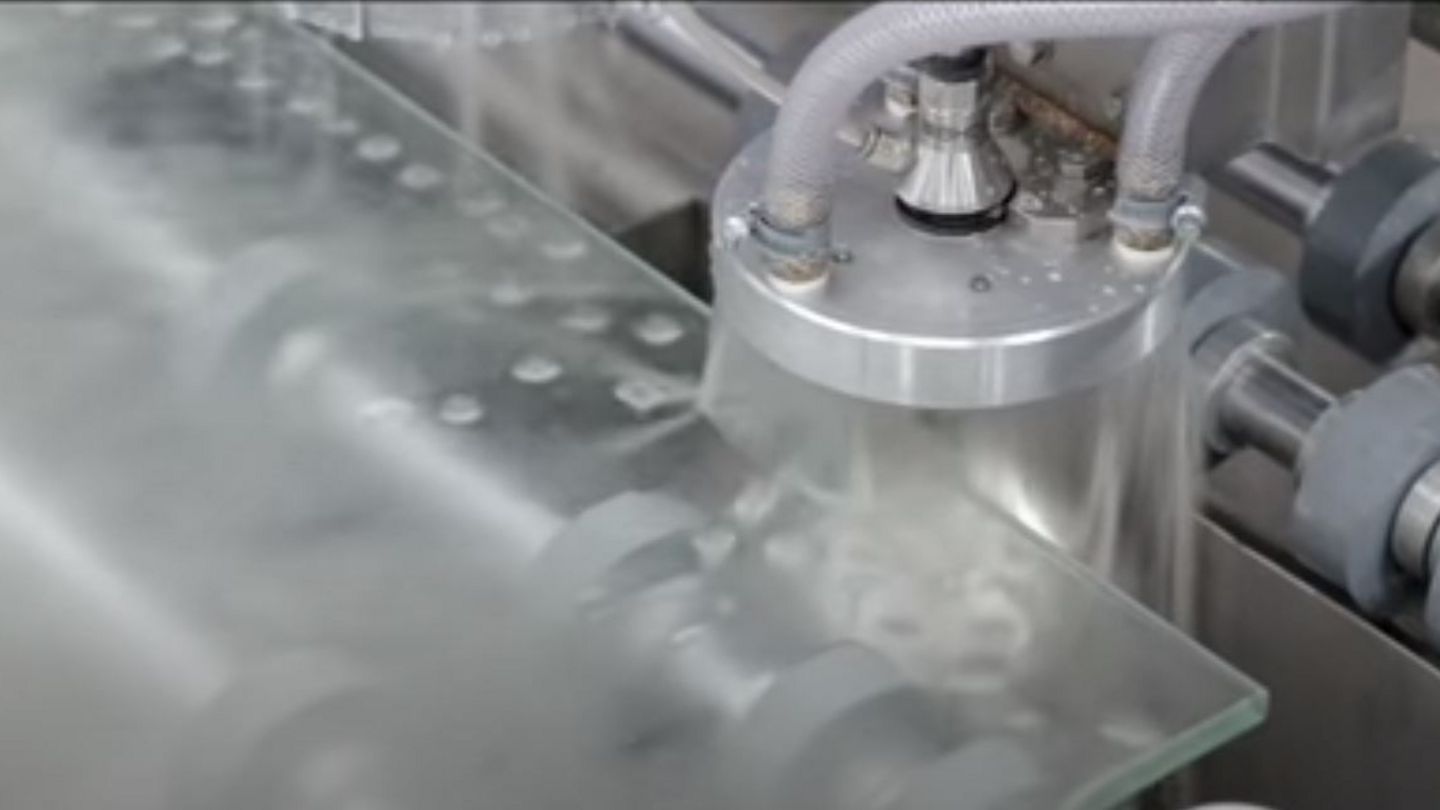

Water-jet Cutting

With this option inner and outer cuts can be produced in a short cycle time with high precision. The edge quality can be increased and the cutouts can be lined, due to an additional milling and seaming spindle.

Advantages

- variable cutting contours, no restrictions by tools

- compared with conventional milling: Process Factor 2.0

- automatic glass disposal of standard cutouts

- suitable for the processing of laminated glass

- water curtain for the protection of surrounding machine components

- controlled capture of the abrasive sand

- radiant energy is absorbed

- specific water flow in separate tanks

- high edge quality

- seaming spindle for seaming / finishing

Technical data

- Max. glass size: 3300 x 20000 mm

- Min. glass size: 250 x 450 mm

- Max. working speed: 15m/min

Fields of application

Architectural Glass

Automotive Glass

Technical Glass

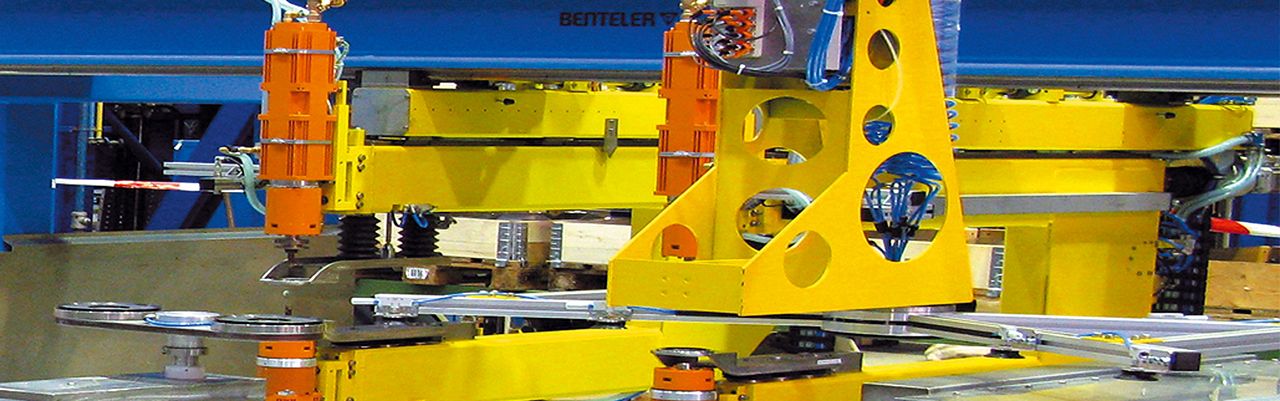

Multispindle Drilling Machines

The BENTELER multispindle drilling machine is a process-reliable and very fast solution for your drilling tasks. The drilling machine can be equipped with up to seven spindle pairs. CNC-controlled axes guarantee a high repeatability with minimal setup time for optimal cost efficiency and high flexibility.

Advantages

High precision

- machine frame and components of especially stable design for low vibration drilling with the high precision and for high repeatability of the drillings

Flexibility:

- simple upgrade of additional drill spindles

Process reliability:

- automatic tool sharpening

- patented Benteler drill spindle drilling motors charged with sealing compressed air for a long service life in wet and abrasive environments

- optional high-speed water removal system, therefore drilling without process water on the glass surface and protection of the sensitive glass surface Simple, comfortable operation

- optional CNC-controlled processing in X, Y and Z directions with an automatic measuring and calibration system for the fully-automatic and precise positioning of the drill

- automatic tool exchange for exchanging tools with minimal output loss

Executions with:

- manual drilling table

- transfer drilling table

Technical data

- Max. glass size: 1300 x 2300 mm

- Repeat accuracy of the borehole placement: ± 0.02 mm

- Positioning speed: 40 m/min

- Number of drill spindle pairs per machine: 1 – 7

Fields of application

Architectural Glass

Automotive Glass

Technical Glass

Vertical Drilling Machines

The BENTELER vertical drilling machine performs fast and precise in your drilling tasks. The drilling machine automatically changes tools in five different sizes. Additionally the machine offers a strong construction with corrosion resistant mechanical design and is suitable for flat and shaped glasses.

Advantages

fast and precise drilling perfomance

- suitable for flat and shaped glasses

Flexibility:

- can be used as a single machine or in combination with the vertical washing machine

Process reliability:

- automatically changing tools in five different sizes

- Front and Rear Spindles at the same time

- Drilling and Countersinking

- Drilling and Countersinking process can be done at the same time

- Countersinking can be done from back and front side of the glass

Technical data

- Max. glass size: 3500 x 2500 mm

- Min. glass sizes: 250 x 600 mm

- workable thickness: 3 -19 mm

Fields of application

Architectural Glass

Technical Glass